Jodi Johnson, CEO, Red Trail Energy, joins The Crude Life to discuss their pioneering project involving carbon capture and storage. Red Trail Energy, LLC (RTE), an ethanol producer near Richardton, North Dakota, is currently operating a CO2 capture facility adjacent to the RTE ethanol facility, to ultimately inject about 180,000 tonnes CO2 annually more than a mile below RTE property for permanent storage.

Red Trail Energy Begins Carbon Capture And Storage

The first carbon capture and storage project allowed under state primacy in the U.S. has commenced operations. Red Trail Energy LLC announces it officially began carbon capture and storage (CCS) at its ethanol facility located near Richardton, North Dakota, on June 16.

Already considered a low-carbon fuel, ethanol produced at RTE now has a lower carbon footprint than conventional ethanol sources thanks to carbon capture. This allows RTE to not only be better stewards to the environment but also places more value on the ethanol in the clean fuel market.

“They (investors) did go out and they gathered enough support that they needed to build it in this area. They somewhat chose this area due to the location next to the Burlington Northern Rail Line,” Johnson said. “Originally, we were constructed to be a coal-fired plant, and so they wanted to be close to where we could get lignite coal to fire the plant and keep it running.”

The RTE ethanol plant emits an average of 180,000 metric tons of CO2 annually from the fermentation process during ethanol production. With CCS, RTE is capturing 100 percent of their CO2 emissions from the fermentation process and is injecting approximately 500 metric tons of CO2 per day. The CO2 is permanently stored underground more than a mile below the surface in the Broom Creek formation.

About Red Trail Energy

Red Trail Energy, LLC (RTE) is a North Dakota-based investor group formed to finance, construct and operate a corn-based ethanol production facility located near Richardton, North Dakota. This vision became a reality when the $99 million, state-of-the-art plant began producing ethanol, in January of 2007. RTE now employs 47 personnel with an annual payroll of $4 million.

Originally constructed as one of the first coal-fired ethanol plants in the nation, RTE was converted to natural gas in 2016. RTE produces 59-64 million gallons of ethanol, using 21-23 million bushels of corn annually. The plant will generate 2.8 gallons of ethanol from every bushel of corn. Coproducts produced by RTE include 125,000 tons of dried distillers grain, 80,000 tons of modified-wetcake and 15 million pounds of corn oil annually.

The Richardton plant’s physical layout is composed of eleven structures, totaling 100,000 square feet of buildings, including administration, maintenance, processing, grain receiving, dried distillers grains storage, coal island, dryers and a pump house. The second-generation plant incorporates all the latest advances in ethanol processing, including equipment and technologies proven to boost efficiency and return on investment.

“One other things that we’ve done is switching from coal fire to natural gas,” Johnson said. “That was definitely a good upgrade for us just because natural gas is a little more consistent fuel source to use than the coal was.”

Governed by a 7 member board, RTE’s Team fosters the future outlook of the plant and its investors, as well as its impact on the environment and economy of North Dakota. Cornerstone Bank is the lead lender for RTE.

Recently, RTE was honored by the Central Stark Soil Conservation District with an Overall Achievement Award.

The Mission of Red Trail Energy is to create economic benefit for our investors, local communities, and the state of North Dakota by converting our natural resources and regional corn production into ethanol and beneficial coproducts.

Collaboration with the EERC (Energy & Environmental Research Center)

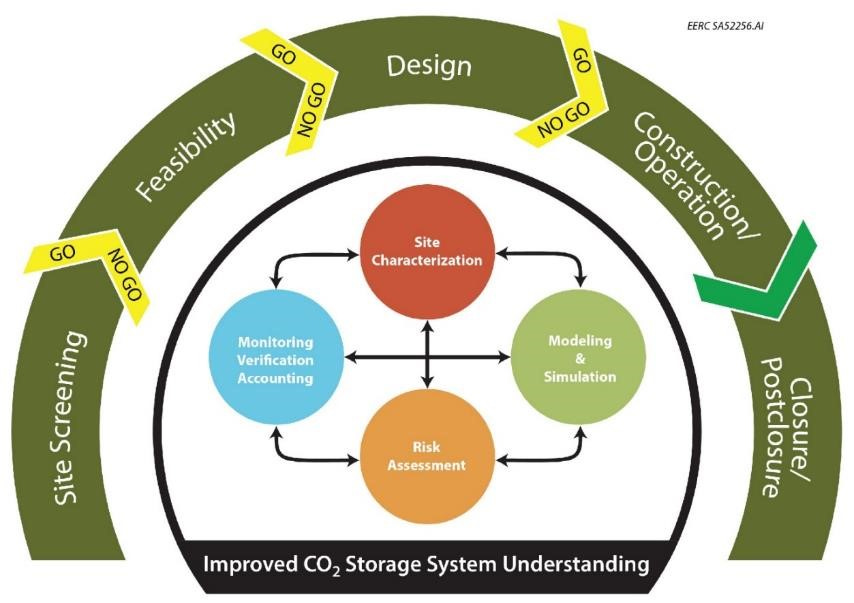

After a 5-year investigative period conducted by the EERC, in partnership with the North Dakota Industrial Commission Renewable Energy Program and the U.S. Department of Energy (DOE), the RTE CCS Project was determined a technically viable option for the significant reduction of CO2 emissions from ethanol production.

The investigation was also supported by the EERC-led Plains CO2 Reduction (PCOR) Partnership, which includes over 200 partners developing and demonstrating technologies for geologic CO2 storage since 2003. Work continues as the project transitions into the first fully operational commercial CCS facility in North Dakota.

In October 2021, less than five months after receiving the RTE application, the North Dakota Industrial Commission approved the Class VI injection well and the reservoir pore space RTE needed to operate the facility. Part of the approval process required RTE to demonstrate the Broom Creek formation contained the characteristics needed for proper CO2 storage. These characteristics include a deep porous layer to absorb the CO2 but also contain impermeable rock layers above and below the Broom Creek formation that keeps the CO2 from escaping into the atmosphere or ground water. RTE is utilizing state-of-the-art monitoring technology from the Japan Research Institute of Innovative Technology for the Earth (RITE) for real time CO2 plume monitoring.

“We are thankful for the North Dakota Industrial Commission and the staff at the Department of Mineral Resources who never gave up on receiving Class VI primacy from the EPA,” said Johnson. “We are especially grateful to the Energy and Environmental Research Center for their dedication to understanding North Dakota’s geologic storage potential, without them this wouldn’t be possible.”

“It is rewarding to see this carbon capture and storage project begin in North Dakota,” said Charlie Gorecki, EERC CEO about the RTE carbon capture project. “The EERC has been researching and testing the geologic storage potential of North Dakota’s resources for decades. The location of Red Trail Energy’s ethanol facility always made it a perfect candidate for CCS.”

Carbon capture and storage is the process of capturing carbon dioxide (CO2) from a large stationary source, compressing the CO2 into a liquid and injecting it via a Class VI injection well deep underground for permanent geologic storage.

North Dakota was the first state to be granted primacy from U.S. EPA in 2018. Wyoming followed in 2020.

Everyday your story is being told by someone. Who is telling your story? Who are you telling your story to?

Email your sustainable story ideas, professional press releases or petro-powered podcast submissions to thecontentcreationstudios(AT)gmail(DOT)com.

#thecrudelife promotes a culture of inclusion and respect through interviews, content creation, live events and partnerships that educate, enrich, and empower people to create a positive social environment for all, regardless of age, race, religion, sexual orientation, or physical or intellectual ability.

CLICK HERE FOR SPECIAL PARAMOUNT + DISCOUNT LINK

The Agency is an American espionage thriller television series for Showtime produced by George Clooney and Grant Heslov and starring Michael Fassbender. The series premiered on November 29, 2024, and is based on the critically acclaimed French series Le Bureau des Légendes, created by Éric Rochant, that aired on Canal+ from 2015 to 2020.

The Agency is now streaming on Paramount+

Share this post