William Ruhle, completions specialist, and Muthukumarappan "Kumar" Ramurthy of Halliburton gives results of their ReFrac ACTIVATE pilot program in the Bakken and their cash flow positive results for oil and gas companies.

Although previous refracturing technologies were unpredictable and not very productive, Halliburton is seeing success with their ACTIVATE refracturing service pilot project.

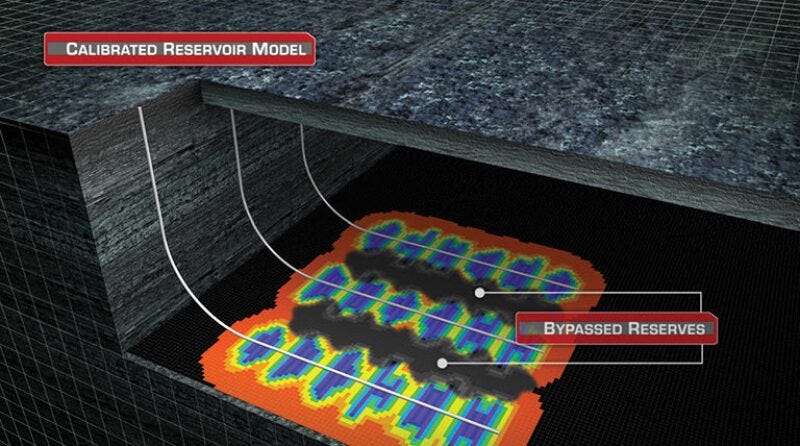

In a nutshell, ACTIVATE is essentially the monitoring of wells with fiber optics and microseismic technology. According to Halliburton, new well completions had less than 60 percent cluster efficiency and fracs of unequal length and width, 80 percent increase in (estimated ultimate recovery) EUR per well, up to 25 percent increase oil recovery factor of unconventional asset with a balanced portfolio, and up to 66 percent reduced cost per barrel of oil equivalent (BOE) compared to new drills.

Additionally, Halliburton reported a 300 percent improvement in EUR in natural gas wells in the Haynesville and Eagle Ford plays on their pilot programs back in 2015.

This is good news for oil companies considering refracs this year. There is some bad news however, not everyone is a candidate for this technology.

“Each of those wells if you follow a candidate’s selection process, that will be filtered to the bottom or to the top. And that will come up as wells as significantly underperforming,” William Ruhle, Completions Engineer, Halliburton said. “Then we identify why they are underperforming. We don’t’ want it to be underperforming because of reservoir quality, or lateral placement. So each of these ones the point has come through on the candidate selection, whether it be an open hole, really vintage completion type, or a more modern completion such as a refracture completion.”

Below is the raw, unedited transcript from our artificial intelligence translator.

Jason Spiess

Halliburton, how do you guys described or defined? Re fracking? Is is that a Webster's term or is that one that you guys came up with yourself or?

Kumar" Ramurthy

Well let William rule take the lead on this and then I will do color commentary and just before we start this, uh, I'm the tech manager for the Rockies, West Coast and Alaska and and William Rule is part of the technology team and he is the axis or the refract

William Ruhle

champion, which

Kumar" Ramurthy

I mentioned before. So

Jason Spiess

William Rule? How do you spell his last name?

Kumar" Ramurthy

Are

William Ruhle

you H. L. E.

Kumar" Ramurthy

We both have different accents. I have the perfect indian accent and William. It may sound different but it is off. So we'll forgive him for that.

Jason Spiess

That was Ossie. Okay, Okay. I was gonna say it sounded like north ST paul, but ...

Kumar" Ramurthy

all right, we'll go with the first question and William can take over.

William Ruhle

So I guess some

Kumar" Ramurthy

re fracturing

William Ruhle

technically any any re fracture is a secondary fracture treatment in a reservoir that's been previously fractured and typically produced for a period of time. I guess the question that some, some people in the industry ... more often, what is the difference between a refract or how do we differentiate a refracts and a re completion? And what we see too often in publications and other studies is people compare production from re fractal re completion operations that have very

dissimilar cost inputs to what we've done at Halliburton we we sub categorize re completions into three categories. What we call re fracture remediation and re entry and what a re fracture is what we would typically consider it in the bark and is going back into an old well utilizing the existing completion and pumping a refract treatment historically.

People of trial trial methods running in with retrievable service tools with today's technology, a rea frac is more typically a treatment pumped through through the casing using chemical diversion. What

Kumar" Ramurthy

we would refer to

William Ruhle

as a remediation is going back into a well that had a failure in the primary completion or in the initial completion. It may be a failure where a sleeve open prematurely somewhere along the well and they've had to forfeit a portion of that lateral on the initial completion and it wasn't and it wasn't remediated at the time the world's auction. So going back into those wells, there's often a larger upfront cost input but there's potentially more more bypass pay so often will go back

in and add new perforations in areas of the lateral that previously weren't perforated and then pump a refract treatment after that. So it's, it's a retract that we also considered a remediation operation um because

Kumar" Ramurthy

it does have some bypass p that was not completed in the early part.

William Ruhle

That's the biggest difference and the additional cost of going in there

Jason Spiess

is that the highest cost. One of those three you mentioned.

William Ruhle

What's that?

Jason Spiess

Would that be the highest cost. One of the re completion. No,

William Ruhle

the cost would be what we call the reentry.

Kumar" Ramurthy

The 3rd part of that,

Jason Spiess

we

William Ruhle

have re fracture remediation and then reentry reentry is where we're going back into existing wells there either completed open hole or most of them were completed. Open hold their vintage wells around the, you know, the 2000 0 before 2010 when multistage fracturing really took off, going back into those old vintage wells and installing a new completion most typically cementing a new liner in.

So they go in, wash and re in lateral, install a new liner cemented in place and then they'll go in and refract that reservoir, but they'll use a multi stage completion. So that that that type of again they're re fracturing because that well was previously refract, you know, 78 years ago, but they're going in installing tubular and then doing a multi stage completion on it or refract

Kumar" Ramurthy

and there are several operators that have done open oil completions and those are the primary targets for

William Ruhle

that

Kumar" Ramurthy

moving in the future. There may not be that many reentry unless some,

William Ruhle

you

Kumar" Ramurthy

know, decide to do that. Open all completions. That's mainly because people did some open all completions and without any liners and

William Ruhle

things like that.

Jason Spiess

Is there a difference of timelines or is it, is it price based and what what what's that trigger mechanism to either go in and do one of those methods of re fracturing? ...

Kumar" Ramurthy

Yeah.

Jason Spiess

Either what reentry or was it remediation or refracting those?

Kumar" Ramurthy

Yeah,

Jason Spiess

just, you know what, what makes you go in and do that? I guess. What's the

Kumar" Ramurthy

trigger? So

William Ruhle

each of those wells, if you follow a candidate selection process they'll they'll be filtered to the bottom or to the top and they will come up as well that have significantly underperforming. And then we identify why they're underperforming. When I say underperforming in production and they need to be underperforming due to the completion. We don't want it to be underperforming due to reservoir quality or wellbore or lateral placement.

So each of these ones at the point has come through the candidate selection whether it be an open hole, really vintage completion type or whether it be a more modern completion such as a re fracture remediation. At that point we need to start assessing what cost input needs to go in and what is the potential reserve optic.

Kumar" Ramurthy

So this is what we call the activist old process. It's called activist refract

William Ruhle

glasses. And

Kumar" Ramurthy

It's basically a four step process.

William Ruhle

The

Kumar" Ramurthy

first one is clearly candidate selection that is very, very, very critical in determining whether that refract campaign will be successful or

William Ruhle

not. And

Kumar" Ramurthy

then we go about designing it. Then the third step is the execution part and finally the complete the loop diagnostics. So it's a four step process which is part of what highly working has grounded has activated?

William Ruhle

What

Jason Spiess

what would be the timeline on? Is there on a well say when the first day of refracting to the last day, does that just depend on each well or does it seem like it falls within a certain parameter?

Kumar" Ramurthy

It basically is asking

William Ruhle

for what is the time to

Kumar" Ramurthy

do this research? There is no silver bullet on that. There's no one size fits all. That's part of our candidate selection process. We will pick that, we will go through a clear thorough process in selecting what are the reasons basically the reason refract is taking off and we can add to the, the current market conditions. But what we are seeing is it will be a balanced portfolio

William Ruhle

kind of thing.

Kumar" Ramurthy

Um this will be part of any company's portfolio in the future, even when the high prices do come

William Ruhle

up

Kumar" Ramurthy

and as you know, in other basins like DJ basin, you know, people have refract cordell two times three times four times they call it track and four track and they still produce very successfully but horizontal, it's a whole different story and that's where the candidate selection process to answer your question specifically that when we go through that process, we can determine when that well is primed for a re

William Ruhle

flak. Yeah, you're referring to the timeline in the life of the world. Right?

Jason Spiess

Yeah.

William Ruhle

So ... it really depends on the production response rather than looking at the timeline for the, well, you know, just on, on a calendar day, we look at the production, we do the production analysis to see what flow regimes going, what flow regime the well is producing in and high grade will force rank candidates that way, obviously reservoir pressure and the amount of drainage previously in that existing well has an influence on how we rank the candidates.

Jason Spiess

And

Kumar" Ramurthy

that's one of the candidate selection process education. And to give you a simple example if the well is in a good area because we do have a clear database, especially in the Bacon and the DJ and other Iraqis areas. We have a vast amount of data base and Qc database.

So we know the subsurface information as well. And if a well performs poorly in that area, then if it is part of that, you know, we don't go do just one. Well we have to do a pilot. You know, operators have gone away from doing single

William Ruhle

wells, you

Kumar" Ramurthy

know, that's how it started, but we do approach it as

William Ruhle

a group

Kumar" Ramurthy

as a pilot

William Ruhle

group.

Kumar" Ramurthy

Okay. Set up 10

William Ruhle

wells and so forth.

Jason Spiess

Um, so there, yeah, there's like steps of the cycle and rather than timelines that was improperly phrased on my end. Um, the uh, so you guys, how many re fracking wells are you guys doing right now? Well, we

Kumar" Ramurthy

do have a database of how many wells we have done, but it's all we can say is operators have started giving one well here and there, but now that was the

William Ruhle

case some time

Kumar" Ramurthy

back. But now they are looking at doing more and more and they're gaining

William Ruhle

momentum?

Kumar" Ramurthy

So

William Ruhle

I mean

Kumar" Ramurthy

we're we're doing reflects on a very consistent basis now gaining traction and we have gained uh there are operators that have

William Ruhle

a

Kumar" Ramurthy

consistent program going on refracts so um I would say it's gaining traction.

William Ruhle

Well yeah it's not gonna happen overnight and we we recognize that definitely the operators who have gone in for a pilot program where they're going to go in and do 6 to 10 wells set themselves up for success. The one they can go through the learning curve and improve and make it more predictable. And also they have a good population of, well there are minimum population of wells to assess the economics on it going out and executing one.

Well, you know what we've seen in some of the pilot programs is often the first, well is the poorest. Well so you can you can overlook the potential of refracts measuring it or just one well. So that that's where we're at with operators. The fire is you know, picking up momentum. Even when we go into a six or 10 world program, we're splitting that up into multiple phases. So we've got time to see production and make improvements. More

Kumar" Ramurthy

than 25 world, I would say in the last

William Ruhle

several

Kumar" Ramurthy

few months or

William Ruhle

so um

Kumar" Ramurthy

in the park and

William Ruhle

and D. J.

Kumar" Ramurthy

It's gaining traction now, much more than

William Ruhle

before. ...

Jason Spiess

And um what was the other thing I was gonna ask you guys on that? How how old is this technology? Is this is this an older technology relatively new? Is it evolving?

Kumar" Ramurthy

So

William Ruhle

Activate activate re fracturing service is a new service that was commercialized this year. What it is is a combination of multiple multiple technology including access crack which is our chemical diversion um technology that was commercialized back in 2011. What differentiates it from from previous technologies or diverted technologies that we've pumped over the decades?

It actually gets into the fracture face bridges off of the fracture faces and diverts from there. So it's not limited on the completion type. You know whether it's un cemented or cemented. Now we've been using that in the bark and consistently on new completions to create facial version. So to create more transverse fractures within a given backstage.

And we've also applied fiber optic technologies on wells. So that's leveraged their learning. We're taking those learnings in new wells and transferring that into the refract world. Now what's improving the refract world and what activates, activates services that couples in those diagnostic technologies. And we've equipped both the ni Brera and the bargain regions with fiber optic coil or fiber coil where they have fiber optic cable inside installed inside a coil

tubing string. And we can go into the well post refract, do a normal clean out as a standard operation and then do what we call a warm back analysis where it measures the temperature along the well bore, it's distributed sensing measures that right along the wellbore and we can identify exactly where that fracturing fluid went and how much went there. What that does is helps us improve each well going through the pilot programs.

Kumar" Ramurthy

So um if I may add a few more comments to that Jason? S this is a technology that's been there forever in the vertical world

William Ruhle

world

Kumar" Ramurthy

now that we are in the horizontal world

William Ruhle

because

Kumar" Ramurthy

of the boom time people were not really thinking about refracts because they were on a factory mode but because of the current market conditions, this is becoming part of the balanced portfolio that I was talking

William Ruhle

about

Kumar" Ramurthy

um where they will have new world infill wells and some refracts the key there is can we get the refracts the program or the pilot than lower than the cost of drilling and completing a new world And if we do that and then it becomes part of the balanced portfolio. So that some of the key technologies that has made this successful as well. Mention one is the diagnostic but the other thing is that something highly Burton have tightened that process.

We call it access strike PSN access strike is part of the diversion technology everybody has diverted but we do have a process and I mentioned Access track PSM that's precious. Think mitigation, that's the one that we have patented. So the way to explain the technology is wealth that have been producing for some time then we go on refract right? So when you produce those well there are depleted areas along the lateral and if you go and do a re flack, those depleted zones will take

away your entire facts. We have data that shows from DPS distributed temperature survey, the diagnostic that will was talking about where one of our competition has prompted job and in one of the world's where we had the distributed temperature survey and we found out that everything goes the entire

William Ruhle

10

Kumar" Ramurthy

or 15 stages went into basically two zones that were depleted no matter how much diversion they put. So that's when we came up with this, we have this process even before that we had learned that that was just a proof for us. We came up with a technology called the PSM pressure sink mitigation where we go in and control these leak up points from stealing away the

entire refract. We will not do a refract without doing a fearsome treatment. That's the biggest differentiation from a technology perspective that we have come up with

Jason Spiess

and and in your your opinion that even if the price went back up this this um this method, this technology, this process is gonna be just kind of integrated into uh an oil company's portfolio. ... Be part

William Ruhle

of the ... Yeah,

Jason Spiess

yeah. The refracts in general as a percentage of way of extracting oil.

William Ruhle

Yes. So

Kumar" Ramurthy

if we look

William Ruhle

At the existing portfolio, that's the objective of the pilot programs to go out to assess the potential of a larger refract program by completing 6 to 10 wells, do the economic assessment on that and then we move into full field development. What what a balanced portfolio is referring to is identifying where refracts have a lower cost per P. O than what new wells or infill wells would be and incorporating those into the portfolio or to the capital expenditure for that given year.

What that will do. What we see the value in a balanced portfolio is is we can high grade which projects high grade projects by their return on investment and where the refracts get incorporated at a lower cost per bot that ultimately drives down the break even point in these plays. So it's really integrating refract technology into their existing portfolios to um to bring down that cost.

Kumar" Ramurthy

And that's the approach we are taking because it makes sense for all the operators to and if we can get a because these worlds at some point in time will be completed again, these are unconventional micro darcy rocks and they need, you know, we're not going to the recovery factors are so low that this can improve that.

Jason Spiess

Yeah, it's nice. It gives them another option. Okay, well, anything else you guys want to add about the uh re fracking that you think should go into an article.

Kumar" Ramurthy

I think the number that I gave is only in the last several months. It's just for us in two days since as a company we have a lot more and I don't have that at the top of my head here because I know my counterparts in the Southeast in Eagle for they have a campaign going with two or three operators and so and the same with mid continent as well. They have a program going there as well. So what I would

William Ruhle

say is,

Kumar" Ramurthy

um, we've come up with

William Ruhle

a four step process and we're implementing that across all these unconventional plays in north

Kumar" Ramurthy

America

William Ruhle

and Halliburton being divided up into several regions across North America. We have strike teams in each of the regions and we're getting together every quarter at a communal point to discuss what learnings we're having in each basin and accelerate our technology across north America by learning from each basin. So we've got a lot of activity in the Haynesville, the marcellus, the Eagle food and the bargain would be the premier in the Rockies region.

Kumar" Ramurthy

So

William Ruhle

we set up very well to transfer our learnings between these plays and help share the learnings.

Kumar" Ramurthy

If I were to, to add to that Jason the three key points, I would stay here as reflux technology is here to stay. Uh, reflux is here to stay and the technology has made that happen through our activate process. We have the four step process and I would say that the candidate selection part of the process is very very important in high grading or downgrading the uh along with the diagnostics and that's number two And number three as well mentioned.

We as a company we have best practices that we have learned over the years that help us improve this process on a day by day basis and we are very comfortable and we and the access track diversion process is a key part in making this. You can. The best way to go and re complete our retractable is to go and put a liner and imitate and do that. But that's not going to be cost effective and that's what we are focused in and the technology development with different mesh sizes in our access

track diversion technology is helping us get there and especially the final point that I would make is any refract will not be a success if we don't have that well prepped what we call the access fry PS um process and that's what we have learned as the biggest takeaway and that's what differentiates us. ...

Jason Spiess

Alright. That sounds good to me gentlemen. Unless there's anything else I'll let you get on with your day.

Kumar" Ramurthy

We appreciate your time. Jason. Thank you so much and will thank you. Thank you. You know when this will publish

Jason Spiess

Um let's see it's uh the next issue of the Bacon Breakout magazine which is put out by the Bismarck Tribune. My guess is probably, you know, in the next 20 days.

Kumar" Ramurthy

Okay. Yeah,

Jason Spiess

I'll make sure that they're aware of it and I'll see if I can't follow up to a lot of times. It takes me about three weeks to get them myself because I'm in Fargo and bismarck. So yeah,

Kumar" Ramurthy

I'm

Jason Spiess

in Fargo, but I do travel out to the back and quite a bit and down into the colorado cabrera area, Rocky Mountains. I'm starting to cover the, I write for a couple of national magazines too. And so, so I know now that the bacon, uh, sex appeal is gone, I'm going to other shale plays, I guess. ... No, it's, you know, it's depends on, I mean, I'm, I'm also doing a presentation where I'm for libraries and, and that sort of thing, doing an educational type thing because, um, and, and, and part of

what I'm telling people is it's, it's a commodity play now, it's, it's like, it's like corn, it's like soybeans, it's, it's a price play and, You know, we've got our infrastructure signed for the next, whatever, five years, $5 billion. So I mean there's gonna be some construction there and then right along with those sweet spot areas. Um,

Kumar" Ramurthy

yeah,

Jason Spiess

Another thing I'm telling. In fact, I was just on, um, uh, statewide radio yesterday and they were asking me about oil prices. And I said, honestly guys, it's pretty good news that we can have $30 oil and still take a million barrels a day out of the ground. So that means that there's there's still some priced oil that's okay. And so that that's kind of how I look at it, but, but I got rid of my television in 2009 and um, I got, you know, so I'm not kind of influenced by a lot of those um

negative news media's. So I guess I I guess I just, when I'm producing the original content, it just makes a little, it makes it a little different, you know, because I don't know that's how, that's how I look at it. So

Kumar" Ramurthy

that's great to know, thank you for your time. We appreciate it and look forward to talking to you.

Jason Spiess

Thanks guys. I appreciate, I appreciate everybody's time and if you need anything, I'm sure you can always reach out to me. Okay?

Kumar" Ramurthy

Alrighty, thank you and have a wonderful weekend. Bye.

Submit your Article Ideas to The Crude Life! Email studio@thecrudelife.com

About The Crude Life

Award winning interviewer and broadcast journalist Jason Spiess and Content Correspondents engage with the industry’s best thinkers, writers, politicians, business leaders, scientists, entertainers, community leaders, cafe owners and other newsmakers in one-on-one interviews and round table discussions.

The Crude Life has been broadcasting on radio stations since 2012 and posts all updates and interviews on The Crude Life Social Media Network.

Everyday your story is being told by someone. Who is telling your story? Who are you telling your story to?

#thecrudelife promotes a culture of inclusion and respect through interviews, content creation, live events and partnerships that educate, enrich, and empower people to create a positive social environment for all, regardless of age, race, religion, sexual orientation, or physical or intellectual ability.

Sponsors, Music and Other Show Notes

Studio Sponsor: The Industrial Forest

The Industrial Forest is a network of environmentally minded and socially conscious businesses that are using industrial innovations to build a network of sustainable forests across the United States.

Studio Email and Inbox Sponsor: The Carbon Patch Kids

The Carbon Patch Kids are a Content Story Series targeted for Children of All Ages! In the world of the Carbon Patch Kids , all life matters and has a purpose. Even the bugs, slugs, weeds and voles.

The Carbon Patch Kids love adventures and playing together. This interaction often finds them encountering emotional experiences that can leave them confused, scared or even too excited to think clearly!

Often times, with the help of their companions, the Carbon Patch Kids can reach a solution to their struggle. Sometimes the Carbon Patch Kids have to reach down deep inside and believe in their own special gift in order to grow.

The caretakers of Carbon Patch Kids do their best to plant seeds in each of the Carbon Patch Kids so they can approach life’s problems with a non-aggressive, peaceful and neighborly solution.

Carbon Patch Kids live, work and play in The Industrial Forest.

Click here for The CarbonPatchKids’ website

Featured Music: Alma Cook

Click here for Alma Cook’s music website

Click here for Alma Cook’s day job – Cook Compliance Solutions

For guest, band or show topic requests, email studio@thecrudelife.com

Spread the word. Support the industry. Share the energy.

The Crude Life Podcast: William Ruhle & Kumar Ramurthy of Halliburton